The high precision and high reliability requirements of aerospace equipment make maintenance and inspection a complex and critical task. Endoscope technology, with its high efficiency, non-destructiveness and real-time imaging, provides important support for the inspection, maintenance and fault diagnosis of aerospace equipment.

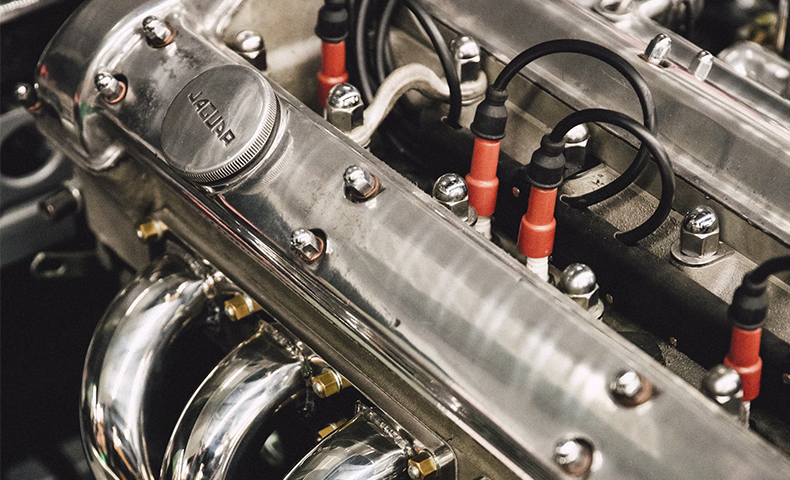

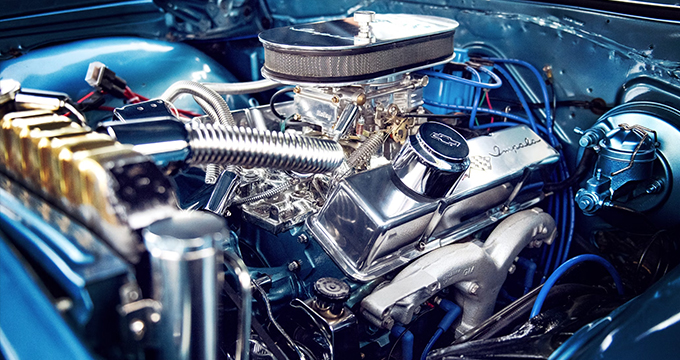

The endoscope goes deep into the engine combustion chamber to check whether the wall has cracks, wear or local ablation. Check whether there is carbon deposits, impurities or local corrosion caused by eddy current inside the nozzle.

Use a flexible endoscope to go deep into narrow spaces to check whether the inner wall of the pipeline is corroded, blocked or cracked.Check whether the cable line is broken, aged or has poor contact.

The endoscope is used to check whether the internal support structure of the insulation board is loose or damaged.Check whether the bonding layer of the thermal protection material is intact.

The endoscope probe can enter the interior of modular components or closed structures to check the looseness of fasteners, cracks in the frame or the status of welding points.In low-light environments, the LED light source of the endoscope can clearly display the inspection area.